The basic principle of metal oxide sensors is the resistance of detection layer changes at the presence of the targeted gasses. Oxidizing gases such as ozone or nitrogen di-oxide the resistance will increase and gases such as carbon monoxide the resistance will go down. These reactions will happen at elevated temperatures and hence. It is one of the main advantages using this sensor is the power required to heater runs are less, compare to other type of sensor, changes in resistance with change in gas concentration is not linear response, and response can be measured and tailored to polynomial relationship. This sensor family are best for instances or trends of gas presence rather than obtaining high accuracy such as sophisticated analytical type systems. For further readings please refer to the datasheet.

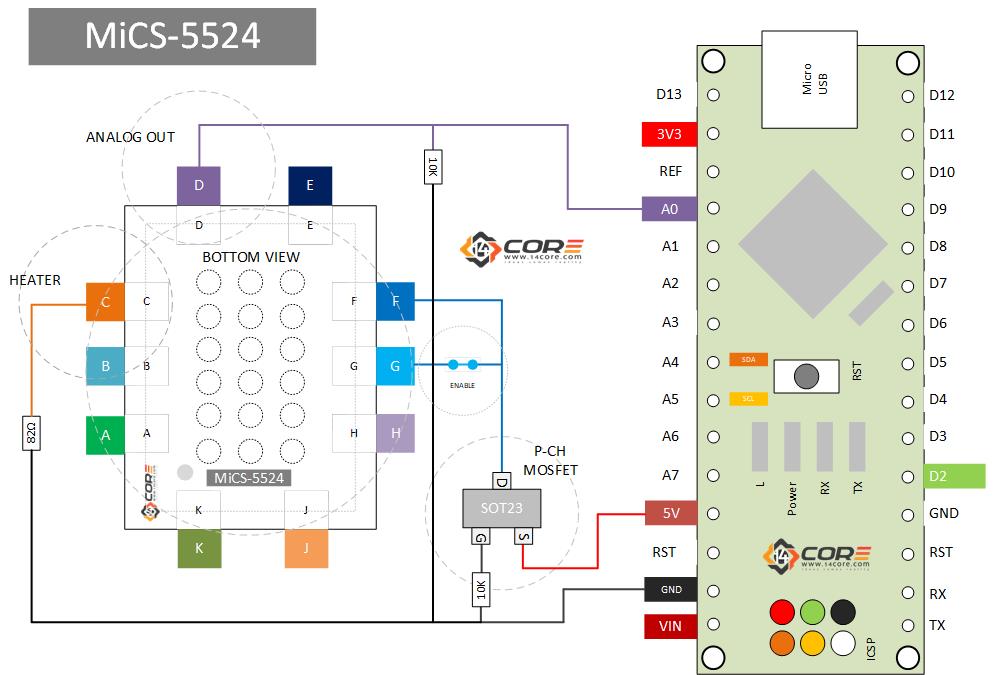

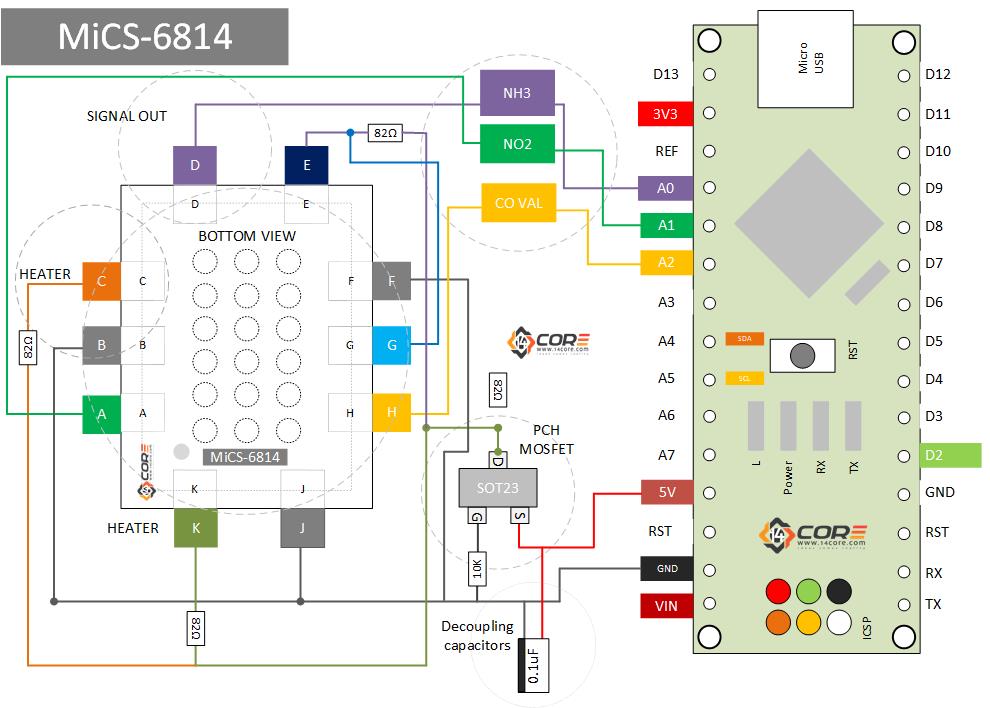

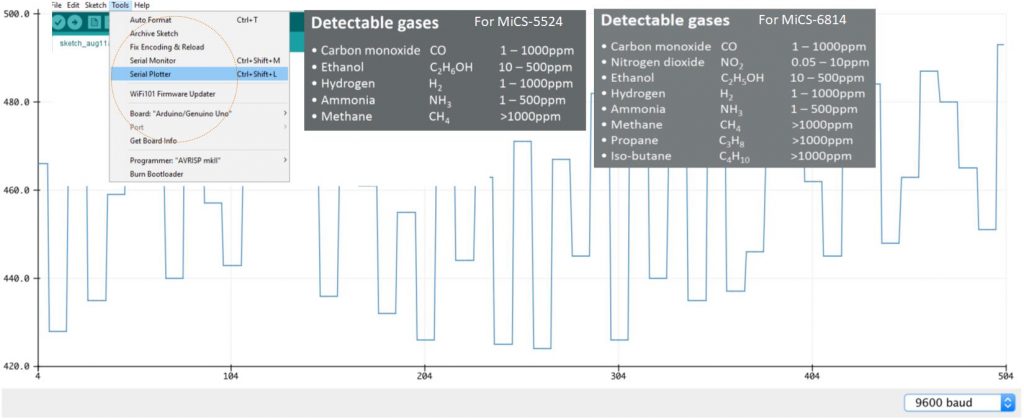

The MiCs 5524 is a compact MEMS metal oxide semiconductor sensor (MOS), suitable for indoor gas detections such as carbon monoxide (CO) at range of 1 ~ 1000 ppm, Ethanol (C2H6OH) range of 10 ~ 500 ppm, Hydrogen (H2) range of 1 ~ 1000 ppm, Ammonia (NH3) range of 1 ~ 500 ppm, Methane (CH4) > 1000 ppm, the 5524 can be used as indoor air quality monitoring, early fire detections, home automations, medical & clinical equipment’s. etc. Compare to MiCs 6814; MiCs 6814 it has 3 sensor chips integrated with independent heaters and can sense up to 8 gases such Carbon Monoxide (CO) range to 1 ~ 1000 ppm, Nitrogen Dioxide (NO2) range to 0.05 ~ 10 ppm, Ethanol (C2H5OH) 10 ~ 500 ppm, Hydrogen (H2) 1 ~ 1000 ppm, Ammonia (NH3) 1 ~ 500 ppm, Methane (CH4) > 1000 ppm, Propane (C3H8) > 10000 ppm, Iso-butane (C4H10) > 1000 ppm. The MiCs 6814 suited for industrial, automobiles, agricultural, pollution detection, air quality sensing. Etc. for more technical details please refer to the datasheet below.

Requirements for this experiment

- Arduino IDE | Atmel Studio | Energia | Processing

- Arduino PRO, FIO, NANO, UNO, MINI, MEGA, PRO MINI, LEO, BT, DUE, ETHERNET,LILYPAD, NodeMCU, Teensy Board, TeensyDuino, ESP8266 12, 12E, ESP32, LinkItOne, ESP8266 NodeMCU, ESPDuino, ATMEGA328 16/12, ATMEGA32u4 16/8/ MHz, ESP8266, MSP430 ,ATMEGA250 16 MHz, ATSAM3x8E, STM32.

- Note: For AVR (please see the flash size of the MCU and respective pin-outs & bus configuration )

- Note: The Diagram below is using NANO. (please refer to each MCU’s respective pin-outs & bus configuration)

- MiCs-5524 Sensor / Module

- MiCs-6814 Sensor / Module

- Capacitors (See below required value)

- Resistors (See below required value)

- PCB Designer (Circuit simulation to PCB Layout / Circuitmaker / fritzing )

Wiring Guide

Source Code

Note: The sensor is sensitive to multiple gasses we cannot tell which is specific gas type detected. Most gas sensor are all same. You need to measure changes in a known gas density not detecting which is changing. For calibrating the sensor, you need to expose the sensor at lease minimum 24 hours is a clean air to acquire a right level of measurement. If you want to obtain a range of concentration you need to carry out an exposure to get a value of constrained gasses at various point and produce a response curve for each value.

Downloads

- Download SGS Sensortech MOS Product Manual | PDF

- Download MiSC-6814 Datasheet | PDF

- Download MiSC-5524 Datasheet | PDF